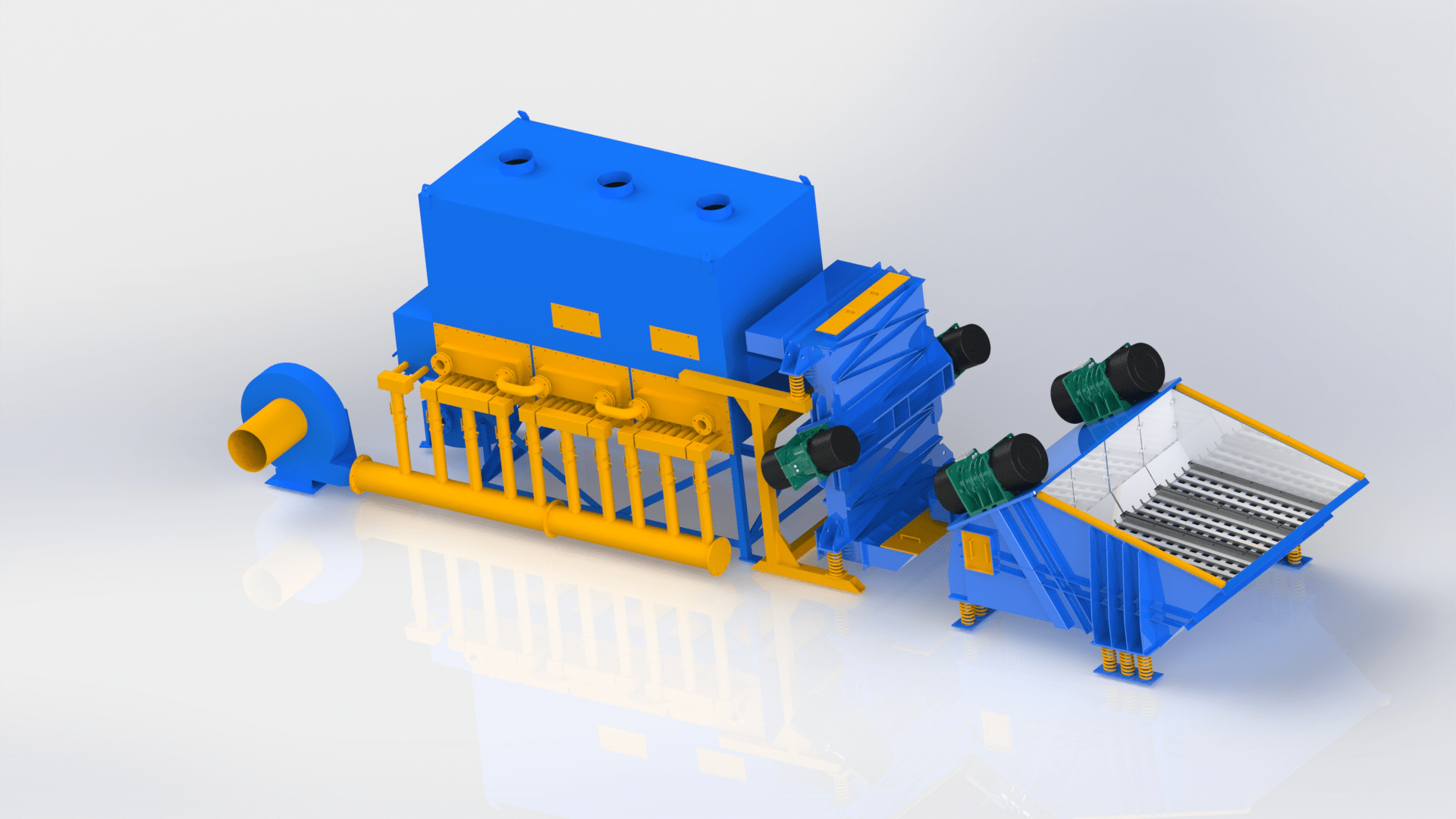

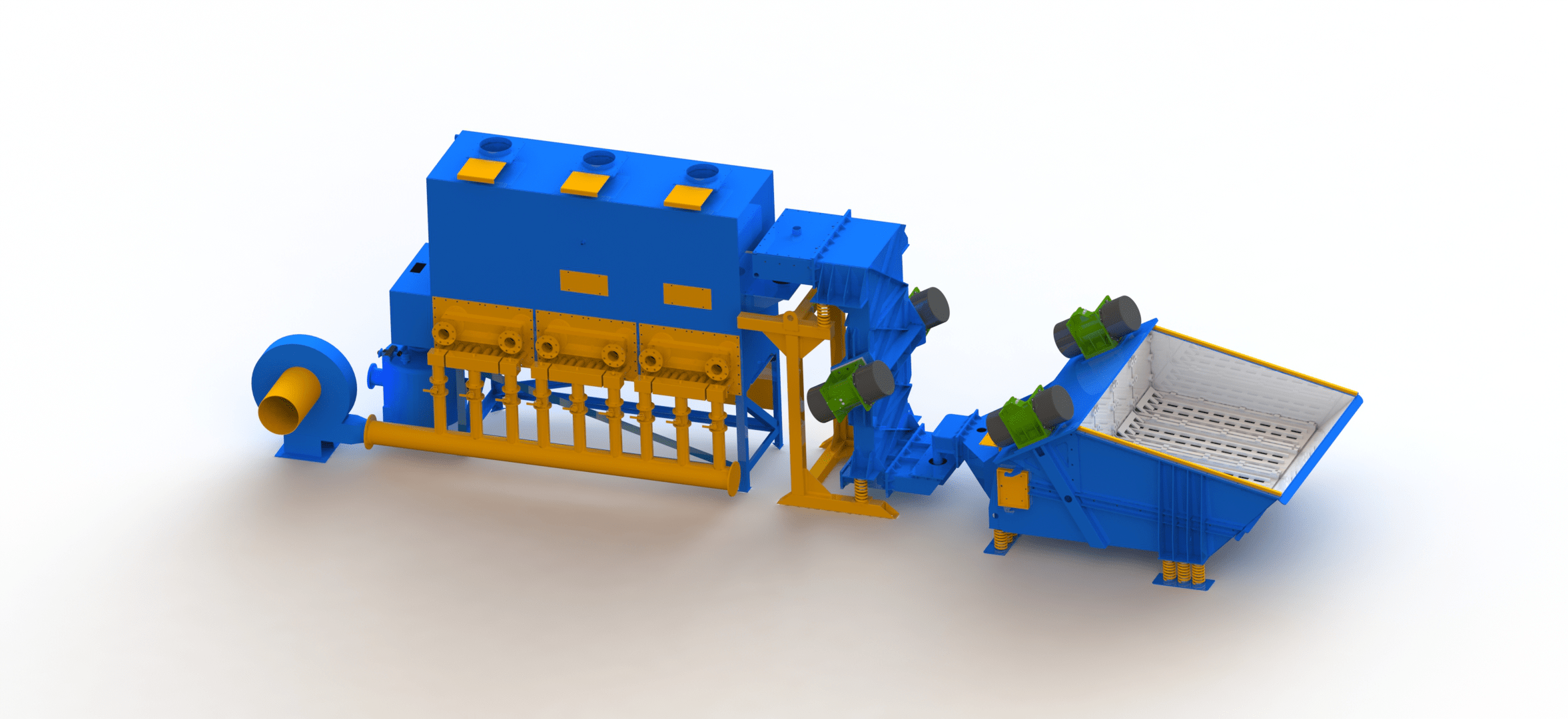

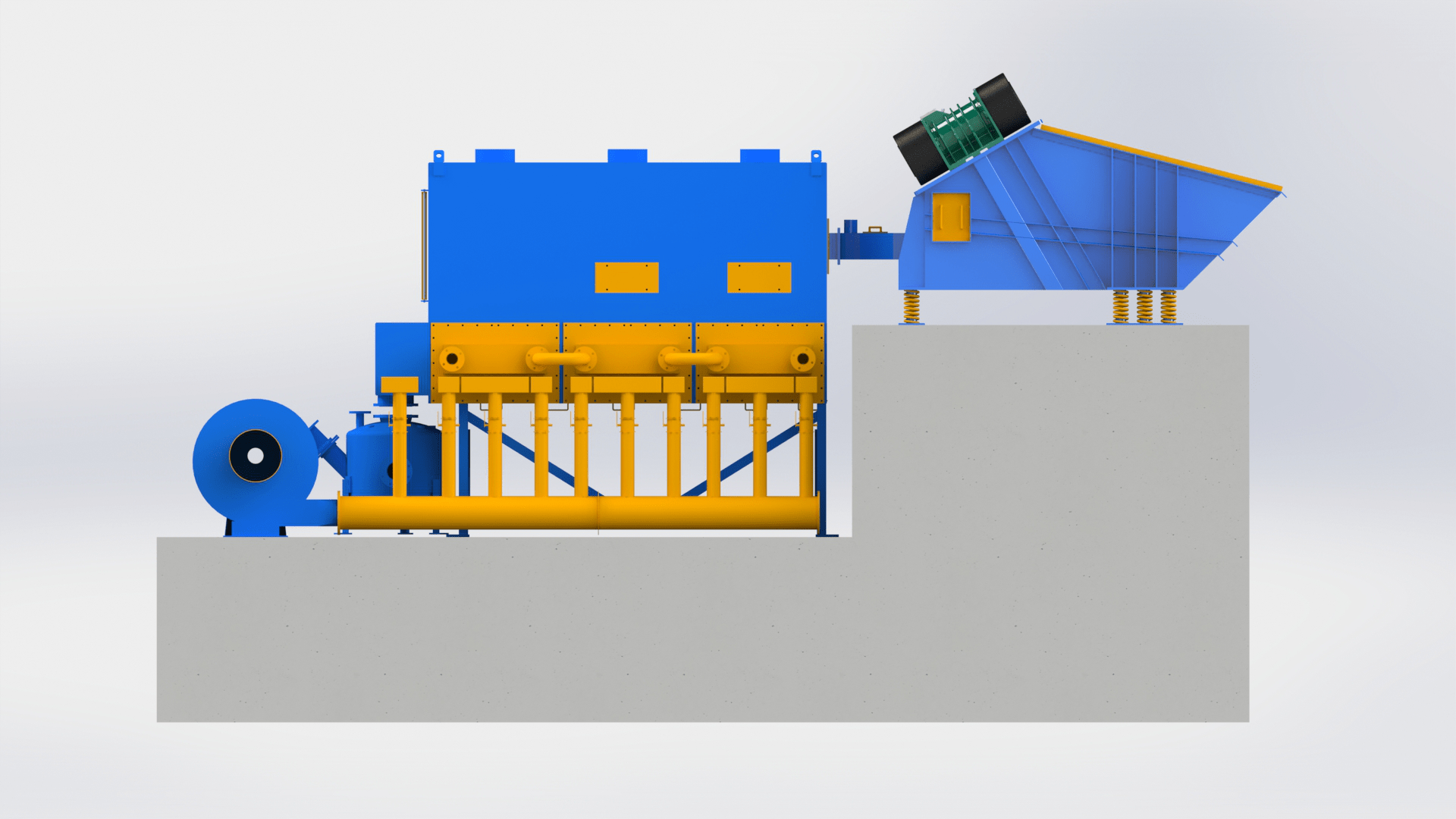

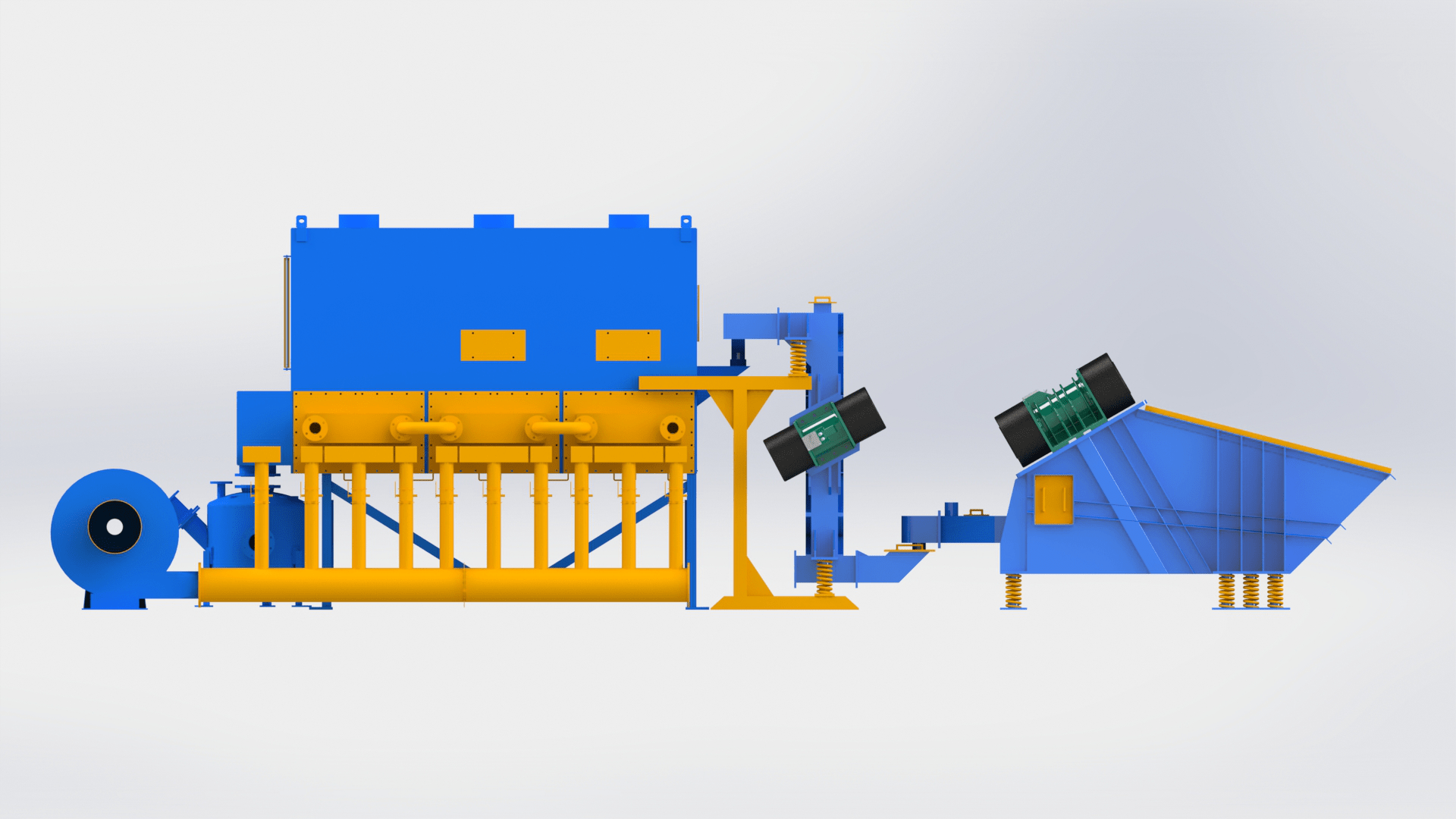

Sarsak is a vibrating machine that allows the molds cast to become sand again

Strong body design

All surfaces where the sand hits throughout the sarsak are covered with hardox material

High reinforcements

Easy maintenance and parts replacement

Laser cut sieves

Throughout the entire system, the sand passes through 6 sieves

Easy sieve replacement

Suitable for working under harsh conditions thanks to the special welding process

Special production vibration damping springs

Heavy duty vibro motors

Easy loading

Vator is a vibrating conveyor that carries the sand

from the sarsak to the cooler-classifier.

Thanks to 90 degree design, it takes up little space

Long life guarantee with Hardox steps

Special production vibration damping springs

Heavy duty vibro motors

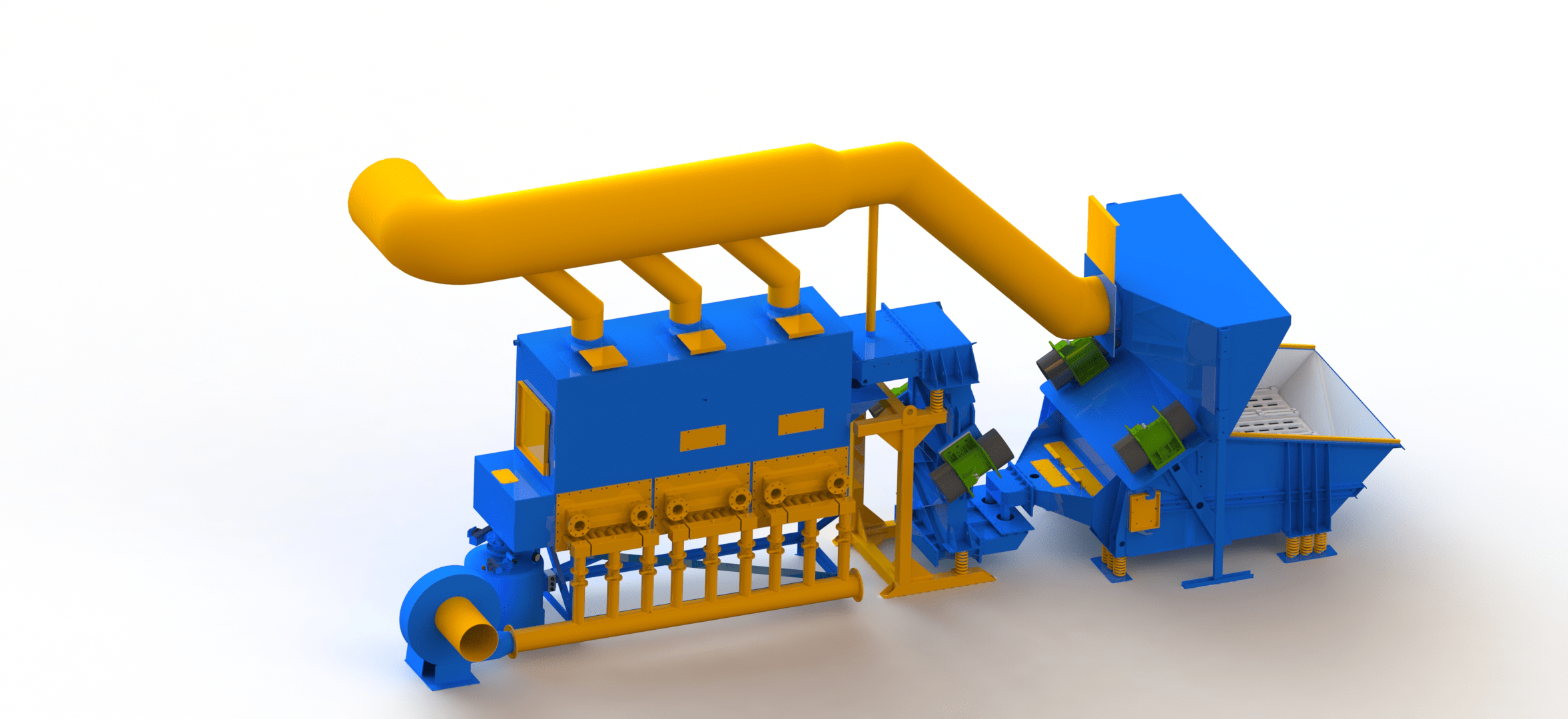

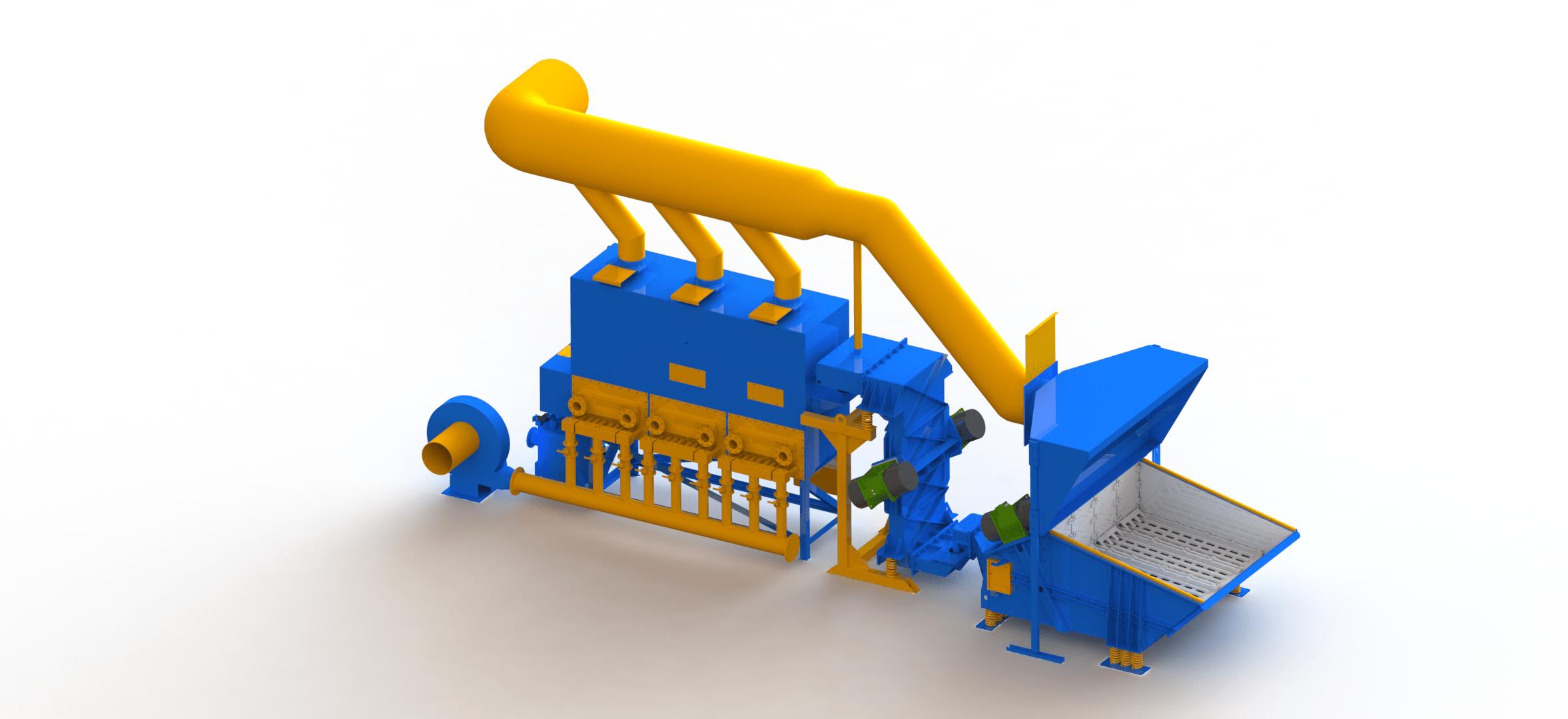

It separates the dust in the sand coming from the shaker with its fluid

bearing system and reduces the sand to the usage temperature.

Air and water cooled.

Works with fluidized bed system.

Flow can be adjusted with air flaps.

Separates the dust in the sand at a high rate.

Low maintenance requirement

Strong construction

Easy disassembly and assembly thanks to bolted connections.

Capacitive level sensor.

High pressure bellows fan

It provides sand shipment with compressor air.

It provides sand shipment with compressor air.

Abrasion resistant butterfly valve

Large sand volume

Special welding

Pressure tested

Less Compressor Energy Required

Fewer Parts Requiring Maintenance

Pressure safety system

High quality capacitive sensor

Lower Operating Costs

Easy to Install